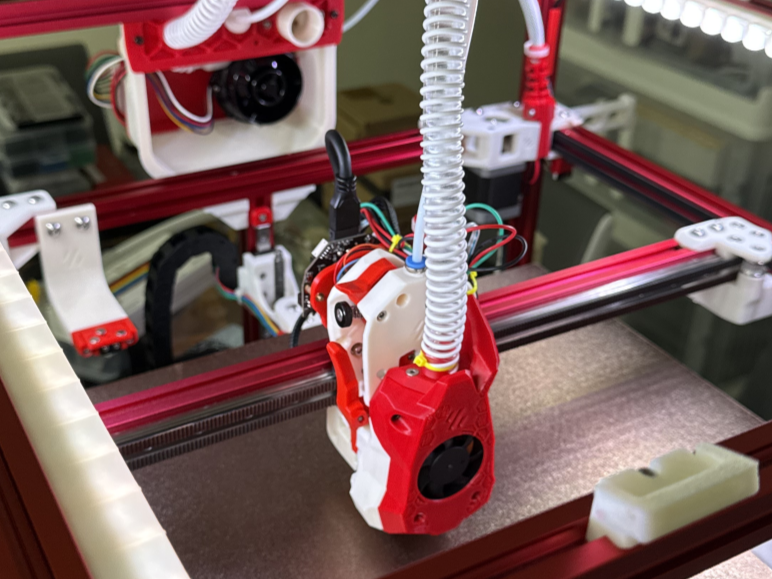

Voron Trident 350mm

High-Performance CoreXY 3D Printer Build

A fully custom-tuned Voron Trident kit build engineered for precision, reliability, and high-speed prototyping.

Tools/Technologies: Voron Trident Kit • Klipper Firmware • CANbus Toolhead • Fusion 360 • Python (Klipper Macros) • ADXL345 Input Shaper • 3D-Printed Custom Parts

Date: Summer 2023

Overview

This project is a complete, from-scratch build of a 350 mm Voron Trident — a high-end, CoreXY 3D printer intended for fast, accurate, and repeatable additive manufacturing. Its purpose was to create a personal fabrication tool capable of producing polished, production-ready parts for robotics, electronics, and mechanical design projects.

The build includes a fully custom Klipper firmware stack, extensive mechanical alignment, and aftermarket upgrades to improve thermal stability, speed, and toolhead performance. Since its completion, the printer has accumulated over 1,500 hours of print time, demonstrating long-term reliability and consistent performance.

My Role

- Performed full mechanical assembly of the printer, including frame alignment using a precision machinist square.

- Assembled the entire electronics bay, wiring harness, CANbus toolhead board, and cable management.

- Installed and configured a completely custom Klipper firmware environment.

- Conducted all tuning procedures: extruder calibration, pressure advance, input shaper/resonance compensation, first-layer offset, cooling calibration, flow rate calibration, and speed tuning.

- Designed and printed custom quality-of-life upgrades (CANbus-compatible Bowden guide arm, door handle, cable tie-down components).

- Integrated major aftermarket upgrades including CPAP “turbo” cooling kit and Klipper screen.

Technical Challenges

- Frame Squaring & Belt Tensioning: Achieving precise mechanical alignment in a CoreXY system required iterative frame adjustments and equalized belt tension to maintain orthogonality at high speeds.

- Klipper Firmware Configuration: Setting up CANbus, tuning resonance compensation, and writing custom macros required careful coordination between firmware, microcontroller layout, and ADXL345 accelerometer data.

- Thermal & Cooling Optimization: The CPAP-based turbo fan system introduced significant airflow; tuning cooling curves and fan ramp behavior was essential to avoid warping and maintain dimensional accuracy.

- High-Speed Print Stability: Pushing print speeds demanded fine-tuning of pressure advance, flow rate, and acceleration limits while balancing ringing reduction and extrusion consistency.

Key Design Decisions

- Adopting CANbus for the Toolhead: Reduced wiring bulk, improved reliability, and simplified future toolhead upgrades.

- Using Klipper Instead of Stock Firmware: Enabled advanced tuning (resonance compensation, macro automation, distributed microcontrollers) and significantly higher performance.

- Upgrading to a CPAP Turbo Cooling System: Provided strong, stable airflow for engineering materials without increasing print head mass.

- Precision Frame Alignment: Ensured long-term mechanical stability, reduced racking, and improved geometric accuracy across the full 350 mm build volume.

Results / Outcomes

- Achieved fast, reliable printing with excellent dimensional accuracy and surface quality after comprehensive tuning.

- The printer has produced parts for robotics, sensor housings, brackets, and mechanical prototypes used throughout my engineering projects.

- Currently maintains 1,500+ hours of successful print time with minimal maintenance and strong repeatability.

- Multiple revision cycles improved cable routing, cooling performance, and firmware macro usability.

- Gained deep hands-on experience in mechanical assembly, firmware configuration, and tuning strategies critical for high-speed additive manufacturing systems.